CT Scanning Technology for Additive Manufacturing in Aerospace

Additive manufacturing has transformed the aerospace industry, creating new possibilities for design and production efficiency. At 3D Engineering Solutions, we understand that these innovative manufacturing methods—while revolutionary—require precise inspection capabilities to ensure component reliability and safety.

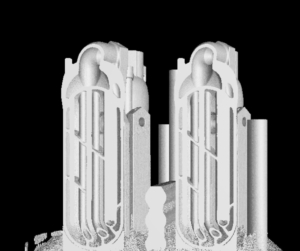

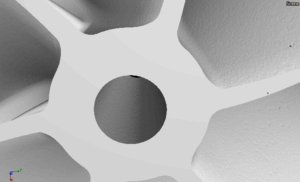

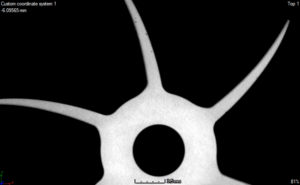

The complex internal geometries made possible through additive manufacturing present unique quality assurance challenges. Internal passages and structures that were previously impossible to manufacture now require thorough inspection to prevent potential performance issues or failures. Since these internal features are one of the primary advantages of additive manufacturing in aerospace applications, having access to advanced inspection technology is necessary.

Aerospace composites add another dimension to these inspection requirements. The sophisticated nature of these materials and their fiber structures demands measurement solutions beyond conventional approaches. Our industrial CT scanning technology addresses these challenges head-on, delivering measurement precision that exceeds industry standards while revolutionizing how aerospace components are validated.

Unlike traditional manufacturing processes and NDT methods that only provide indirect indications of a component’s quality, our industrial x-ray services offer direct visualization of both the external and internal structures of additively manufactured aerospace parts. This gives engineers and quality specialists the data they need to verify component integrity with confidence. By combining our engineering expertise with cutting-edge technology, we help aerospace manufacturers ensure the performance, reliability, and safety of their additively manufactured components.

New Solutions with Industrial CT Scanning

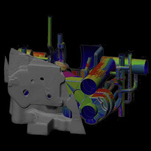

For production of parts for aerospace, industrial CT scanning brings incredible advantages that were previously impossible with traditional scanning methods. Before, assemblies would have to be disassembled and each part checked individually. Not only was this time consuming, but parts could be destroyed or damaged in the process. CT scanning allows us to check an entire assembly at once, in the assembled state. This non-destructive method of testing ensures each part will also function correctly in unison. Internal and external features can be inspected simultaneously, saving huge amounts of time in the inspection process.

Unmatched Defect Detection

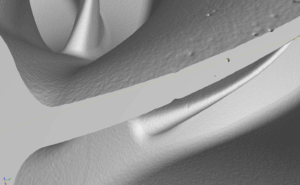

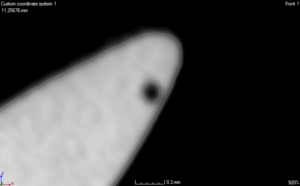

Detecting voids through porosity analysis has never been more accurate as well. CT scanning allows us to find previously undetectable imperfections with the manufactured assemblies. We can now detect thin walls and possible faults in assembly designs with certified precision.

Considering the multiple benefits of CT scanning, it is a perfect solution to ensuring accurate inspection of aerospace and additive manufacturing components.

Understanding Additive Manufacturing Processes in Aerospace Applications

At 3D Engineering Solutions, we use our engineering expertise to help aerospace manufacturers maximize the benefits of additive manufacturing technology. Unlike traditional subtractive methods that remove material from a solid block, additive manufacturing builds components layer by layer from digital models, creating new possibilities for aerospace design and production.

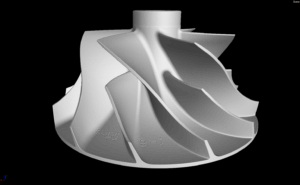

This approach enables aerospace manufacturers to create complex geometries with a precision that was previously unattainable. From lightweight components with intricate internal structures to consolidated parts that reduce assembly requirements, additive manufacturing in aerospace is driving innovation across the industry.

The Additive Manufacturing Workflow

The additive manufacturing process follows a streamlined digital workflow that transforms concepts into physical components:

- Digital Design Creation: Components begin as 3D CAD models, designed specifically to leverage the unique capabilities of additive manufacturing.

- File Preparation: These designs are converted to STL or AMF files and then processed through slicing software that creates the layer-by-layer instructions.

- Build Setup: Parameters are optimized for the specific aerospace application, material, and quality requirements.

- Manufacturing: The component is built layer by layer according to the digital instructions.

- Post-Processing: Depending on the application, components may undergo heat treatment, surface finishing, or additional machining.

- Inspection: Aerospace components require validation through advanced inspection methods like our 3d laser scanning services and CT scanning.

Our team works with various additive manufacturing technologies relevant to aerospace applications, including Selective Laser Melting (SLM) for metal components, Electron Beam Melting (EBM) for titanium structures, and advanced polymer processes for tooling and non-structural components. Each technology offers advantages for different aerospace applications, from lightweight brackets and complex ducting to heat exchangers and fuel system components.

As additive manufacturing in aerospace continues to evolve, our measurement and inspection capabilities keep pace, ensuring that even the most complex additively manufactured components meet the industry’s exacting standards for performance and reliability.

Overcoming Additive Manufacturing Challenges in Aerospace

The aerospace industry faces unique inspection challenges when utilizing additive manufacturing technologies. At 3D Engineering Solutions, our advanced CT scanning capabilities directly address these obstacles:

- Complex Internal Geometry Verification: Traditional inspection methods cannot adequately assess the intricate internal channels and structures that make additive manufacturing so valuable for aerospace applications. Our industrial CT scanning technology provides complete visualization of these complex internal features without damaging the component.

- Material Consistency Validation: Additive manufacturing can introduce material inconsistencies that affect component performance. Our inspection technology detects variations in material density, fusion quality, and microstructural integrity that might otherwise remain hidden until component failure.

- Assembly Inspection Without Disassembly: Many aerospace components function as part of complex assemblies. Our CT scanning services enable inspection of fully assembled components in their operational configuration, eliminating the risks associated with disassembly and reassembly for inspection purposes.

- Qualification and Certification Support: Additively manufactured aerospace components require thorough documentation for certification. Our ISO/IEC 17025 accredited inspection services provide the detailed reports and verifiable data needed to satisfy rigorous aerospace certification requirements.

- Design Iteration Efficiency: Refining designs for additive manufacturing requires precise feedback. Our detailed inspection reports identify opportunities for design improvements, helping aerospace manufacturers optimize components for both performance and manufacturability.

The 3D Engineering Advantage

3D Engineering Solutions brings over 100 years of combined manufacturing and design experience to your aerospace additive manufacturing projects. As an ISO/IEC 17025 certified inspection provider, we deliver the precise measurements and analysis needed to ensure your additively manufactured components meet the most demanding aerospace standards.

Our state-of-the-art industrial CT scanning technology allows us to inspect complex internal geometries and detect potential defects without damaging your valuable components. We understand the unique challenges of aerospace manufacturing and provide fast, cost-effective solutions with industry-leading accuracy.

From first-article inspection to production quality assurance, our team of degreed engineers supports your additive manufacturing process with detailed reports and expert analysis. Our documentation enhances your audit capabilities and helps maintain compliance with aerospace industry requirements.

When precision and reliability matter most, 3D Engineering Solutions delivers the advanced metrology services aerospace manufacturers need to succeed. Our commitment to quality, attention to detail, and engineering expertise make us the trusted partner for aerospace inspection needs.

Frequently Asked Questions

How does the additive manufacturing process differ from traditional manufacturing processes for aerospace components?

Additive manufacturing builds aerospace components layer by layer from digital models rather than removing material from a solid block, as in conventional manufacturing. This approach enables design optimization for weight reduction and performance enhancement while reducing material waste. 3D Engineering Solutions helps aerospace manufacturers validate that these components meet all dimensional and performance requirements.

What types of defects can be detected in additively manufactured aerospace components?

Common defects in additively manufactured aerospace components include porosity, incomplete fusion, cracking, and geometric inaccuracies. Our industrial CT scanning technology can detect these issues throughout the entire component, including in complex internal passages. 3D Engineering Solutions provides detailed reports with precise measurements and visualization of any detected anomalies.

What materials are commonly used in additive manufacturing for aerospace applications?

Aerospace-grade additive manufacturing typically utilizes titanium alloys, nickel-based superalloys, and specialized aluminum alloys. These materials provide the optimal combination of strength, weight, and thermal properties required for demanding aerospace environments. 3D Engineering Solutions offers inspection services for all commonly used aerospace materials, ensuring quality regardless of material selection.