Precision Casting Inspection Through Industrial CT Scanning

Understanding Casting Inspection Fundamentals

Ensuring near identical dimensions in the casting manufacturing process can be done through a number of scanning methods. While all scanning processes have inherent advantages and disadvantages, our most advanced technology is made possible by industrial CT scanning. Engineering and manufacturing a reliable part requires absolute confidence that the testing results are accurate. CT scanning allows for surgical precision, guaranteeing a report you can trust.

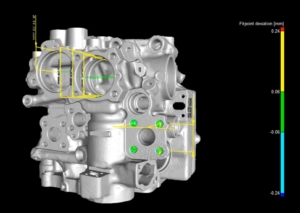

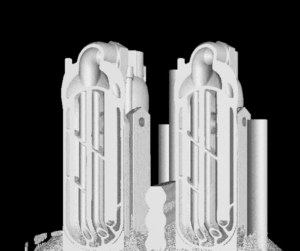

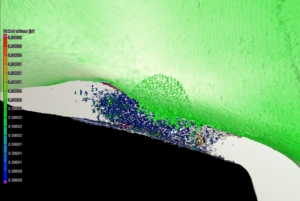

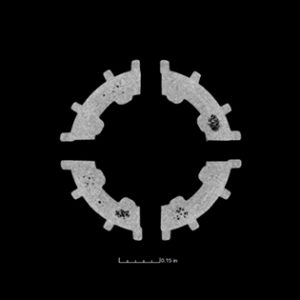

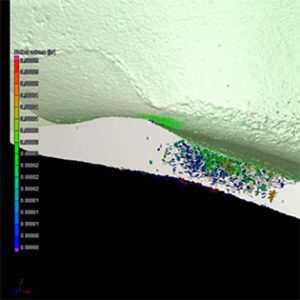

Utilizing this new technology, we can scan an entire piece and map even the smallest details. Checking wall thickness and possible flaws can catch manufacturing issues early, saving time and money in the process. A porosity analysis gives a high-dimensional accuracy scan that captures both internal and external features. The advantage of eliminating the need for line-of-sight scanning allows for multiple layers of an assembly to be tested at once. Previous methods would require dissembling or even damaging the product to allow a full scan. The capabilities of industrial CT scanning can also save time, money, and resources in the testing process.

Industrial CT Scanning for Cast Parts

3D Engineering Solutions brings specialized CT scanning technology to the inspection of cast parts and components. Our casting inspection procedures use advanced technology to inspect cast metal parts inside and out, providing manufacturers with valuable insights without damaging or sectioning components.

While traditional inspection methods might require cutting or sectioning castings to check internal features, our CT scanning technology lets you see inside your castings while keeping them intact for further processing or assembly. This lets you verify part quality without wasting valuable components.

For cast parts, CT scanning shows:

- Hidden air pockets or holes inside the metal

- How thick the walls are throughout the part

- Exact measurements of internal features

- How well parts will fit together

- Flaws that might be invisible from the outside

CT Scanning Equipment for Casting Analysis

Our facility houses multiple CT systems for inspecting cast parts:

Metrology-Grade 225kV MCT Systems

Our 225kV MCT Nikon machines represent the highest standard in metrology-grade CT scanning. These systems operate in temperature-controlled environments for extremely accurate measurements. They’re certified under ISO 17025 standards, which means our measurements are officially recognized for their accuracy.

450kV Micro-Focus System for Dense Materials

For thicker or denser metal castings (like iron or steel), we use our more powerful 450kV Nikon system. This machine can see through thick metal while still showing fine details. It uses special detector technology to capture crisp, clear images even through the densest materials.

For all cast part inspections, we use Volume Graphics VG Studio Max software to process and analyze the CT data. This specialized software handles the voxel data from our scans, allowing us to extract meaningful measurements and visualize important features within your castings.

Quality and Expertise

As with all our inspection services, our casting inspection work is performed by degreed engineers with specific training in CT technology and inspection techniques. Our ISO 17025 accreditation confirms our measurement capabilities meet stringent international standards. Our casting inspection capabilities complement our broader range of industrial X-ray services available at our Cincinnati facility.

Located conveniently in Cincinnati with access to I-75 and I-275, our facility operates 24/7 to accommodate time-critical inspection needs. This round-the-clock availability means we can support manufacturing operations with minimal disruption to production schedules.

Contact Us

For more information about how our CT scanning services can improve your quality casting verification, call us today at 513-771-7710. You can also visit our website to request a quote for your specific inspection requirements.

The 3D Engineering Solutions Difference

Our Service

Speed matters in today’s manufacturing environment. At 3D Engineering Solutions, we don’t just talk fast—we deliver fast. Our scanning systems capture up to 1,000,000 data points per second, and our 24/7 operation means your projects don’t wait for business hours.

We’ve built our reputation on having the right tools for each job. From our Cincinnati headquarters, we deploy multiple digitization technologies backed by specialized point cloud software to transform raw data into actionable quality insights. This combination breaks through typical production bottlenecks and keeps your projects moving forward.

Our engineering metrology services work across industries—aerospace, automotive, medical, consumer products, tool and die, forensics, archaeology, motion picture, and more. Anywhere that needs precise 3D digital models, we deliver results that meet exacting standards.

When quality issues demand immediate attention, think of us as your on-call metrology department. We bring testing equipment and engineering expertise wherever it’s needed, from local manufacturers to international operations. Our mobile capabilities mean the measurement lab comes to you when circumstances require it.

Our People

The real difference at 3D Engineering Solutions is our team. With over 150 years of combined manufacturing and engineering experience, our staff knows how to sweat the details that matter to your project’s success.

Every team member brings hands-on industry knowledge to your challenges. Our degreed engineers specialize in diverse fields, including:

- 3D scanning and reverse engineering

- Quality assurance and inspection

- Dimensional analysis

- Part-to-CAD comparison

- Expert witness consulting for engineering matters

- Industrial CT scanning and analysis

This blend of technical expertise and practical manufacturing experience means we understand not just how to collect measurements, but what those measurements mean for your products and processes.

Our Technology

We continuously invest in measurement technology that delivers the precision modern manufacturing demands. Our equipment combines high-speed data collection with exceptional accuracy, whether using touchless laser scanning, industrial CT, or structured light systems.

Through partnerships with industry-leading technology providers, we maintain cutting-edge capabilities while ensuring reliability and support. These relationships help us deliver both standard and custom measurement solutions tailored to your specific requirements.

Your success drives our approach to technology selection and implementation. By combining superior communication, attention to detail, and innovative measurement techniques, we help you solve quality challenges and improve engineering outcomes.

At 3D Engineering Solutions, our commitment is simple: we apply the best measurement technology and engineering expertise to deliver the precise data you need, when you need it.

See for yourself how industrial CT scanning can expose unseen faults in a part’s design:

Industrial CT Scanning White Paper

Frequently Asked Questions

What advantages does CT scanning offer for casting inspection?

CT scanning allows us to inspect internal features without damaging your castings. We can check wall thickness and identify possible flaws without disassembling or sectioning the part. The technology captures both internal and external features in a single scan.

Who performs your casting inspections?

Our casting inspections are performed by degreed engineers with extensive experience in both CT technology and manufacturing. Our team has a combined 150+ years of industry experience. Every engineer is specifically trained on our equipment and software.

What other services do you offer beyond casting inspection?

Beyond casting inspection, we provide 3D scanning, reverse engineering, quality inspection, and various other measurement services. We work with industries including aerospace, automotive, medical, and manufacturing. Our engineers can also serve as expert witnesses for engineering-related matters.