Accurate Digital Surface Model Services for Precision Manufacturing

3D Engineering Solutions offers a wide range of services pertaining to freeform surface modeling, including the creation of both class A and class B surfaces. Our NURBS modeling and parametric surfacing experts work with clients, helping perfect details of each project. To verify geometric specifications of freeform surfaces, 3D Engineering uses both contact and non-contact measuring devices.

What is a Digital Surface Model?

In manufacturing and engineering applications, a Digital Surface Model (DSM) refers to the precise digital representation of a physical part’s surface geometry. At 3D Engineering Solutions, we create these models using point cloud data collected through our advanced scanning technologies to capture the exact surface characteristics of manufactured components and assemblies.

Our digital surface models provide accurate geometric data that serves as the foundation for reverse engineering, quality inspection, and manufacturing applications across multiple industries.

3D Engineering Solutions specializes in freeform surface modeling, including the creation of both Class A and Class B surfaces. Our NURBS modeling and parametric surfacing engineers work directly with clients to capture every detail of their components. To verify geometric specifications of freeform surfaces, we use both contact and non-contact measuring devices in our ISO 17025 certified metrology lab. Our point cloud software allows us to deliver precise surface models that meet the demanding requirements of industries including aerospace, automotive, manufacturing, and medical device production.

Understanding DSM Technology

Our digital surface modeling process utilizes advanced 3D scanning technologies including laser scanning, structured light scanning, and industrial CT scanning. Through these non-contact measurement methods, we generate highly accurate surface data that is accurate to within our published measurement uncertainties. Our scanning systems capture millions of data points to create surface models that accurately represent even the most complex geometries.

Key Features and Components

Our digital surface modeling services include several capabilities that set us apart in the metrology industry:

- High-Resolution Data Collection: Our scanning systems collect up to 1,000,000 points per second with exceptional accuracy

- Multi-Technology Approach: We employ laser scanning, structured light scanning, and CT scanning to capture complete surface data

- Certified Measurements: Our ISO 17025 accreditation ensures reliable and traceable surface measurement data

Advantages Over Traditional Measurement Methods

Digital surface models provide significant advantages over traditional measurement approaches. With our scanning technologies, we can capture complete surface geometry in a fraction of the time required by conventional measurement methods. Our non-contact scanning methods avoid disturbing delicate or flexible parts while providing surface data that would be impossible to obtain through traditional touch probe methods alone.

Applications Across Industries

Our digital surface modeling services support manufacturing and quality requirements across multiple industries. From aerospace components to medical devices, our surface models provide the precision data needed for critical applications.

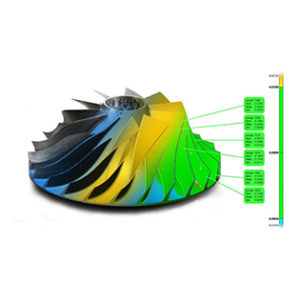

Aerospace

In the aerospace industry, our surface modeling services support the inspection and reverse engineering of complex aircraft components. We create precise surface models of turbine blades, engine components, and structural parts to support manufacturing, repair, and modification processes. Our models help aerospace manufacturers maintain the tight tolerances required for flight-critical components.

Automotive

The automotive industry relies on our surface modeling for both production parts and tooling applications. We create Class A surfaces for exterior body panels and complex interior components, supporting both original equipment manufacturers and tool and die shops. Our surface models are used in the design and manufacture of stamping dies, injection molds, and other automotive tooling.

Manufacturing

Manufacturing companies use our digital surface models for tool and die repair, legacy part reproduction, and quality control applications. When original CAD data is unavailable or tooling requires modification, our surface models provide the precise geometric data needed to maintain production continuity.

Medical

In the medical device industry, our surface modeling supports the development and manufacturing of implants, surgical instruments, and diagnostic equipment. We create precise surface models that meet the stringent quality requirements of medical device manufacturing, supporting both prototype development and production applications.

Why Choose Our Digital Surface Models

3D Engineering Solutions brings over 150 years of combined industry experience to every surface modeling project. Our approach combines advanced scanning technology with deep engineering expertise to deliver surface models that meet the most demanding manufacturing requirements.

Our ISO 17025 certified metrology lab houses state-of-the-art equipment including multiple laser scanning systems, structured light scanners, and industrial CT machines. This toolset allows us to select the optimal measurement approach for each component, whether you need Class A surfaces for aesthetic applications or Class B surfaces for functional requirements.

The Making of a Digital Surface Model

Our digital surface model creation process begins with selecting the appropriate scanning technology for your specific component. We employ laser scanning for large parts and assemblies, structured light scanning for detailed surface capture, and industrial CT scanning for internal and external surface analysis.

Our degreed engineers use advanced point cloud processing software to convert raw scan data into precise surface models. We create these models in your preferred CAD platform – whether Siemens NX, SolidWorks, Creo, or Revit – ensuring seamless integration with your existing design workflow.

Accuracy of Our Digital Surface Models

Accuracy is fundamental to our surface modeling services. Our scanning systems provide measurement capabilities ranging from 0.0002″ to 0.0035″ depending on the technology and application requirements. For contact probe scanning, we achieve accuracies in the 0.0001″ to 0.0003″ range.

We verify every surface model through scan-to-CAD comparison analysis, ensuring that our digital representations accurately match the physical part data. Our ISO 17025 certification requires us to estimate and report measurement uncertainties, giving you confidence in the reliability of our surface models.

Digital Surface Models for Manufacturing Applications

Our digital surface models support manufacturing processes including tool and die design, mold creation, and production part inspection. When tooling breaks or requires modification, our surface models provide the geometric data needed to restore production quickly.

The high-resolution surface data we capture makes our models ideal for manufacturing applications where precise surface geometry is necessary. Our models support both prototype development and high-volume production requirements across multiple industries.

Digital Surface Model Process Setup

For larger volumes of serialized components, we implement process control and documentation through systematic tracking when required. Individual surface models can be stored with serialized information for future review, customer disposition, verification, or long-term storage. As needed, we can provide documentation indicating that surface modeling and inspection has been completed on specific parts or batches.

We employ onsite 3D printing of custom fixtures for repeatable positioning of parts between scans. This allows your surface models to be created in consistent orientations part after part. Each of our engineers is trained in one of our multiple CAD platforms and the use of our 3D printer to create custom polymer fixtures for their work. When higher precision is required for large-scale projects, fixtures are machined to specification using outside suppliers as needed.

We are also able to perform surface modeling projects to specific industry standards and customer specifications. We can accept and follow your internal quality requirements and dimensional standards throughout the surface modeling process. Our ISO 17025 certification ensures that our measurement and modeling processes meet rigorous quality standards.

Our systematic approach includes proper documentation of measurement methods, equipment used, and environmental conditions during data collection. This documentation supports traceability requirements and provides the measurement uncertainty information needed for critical applications. Whether you have a single prototype component or a full production run requiring surface models, 3D Engineering Solutions provides the process control and documentation needed to support your quality requirements.

About Our Team

3D Engineering Solutions is a leading provider of advanced engineering metrology services, combining over 150 years of collective industry experience with state-of-the-art measurement technology. Based in Cincinnati, Ohio, our 24,000-square-foot temperature-controlled facility houses one of the region’s most comprehensive metrology laboratories and training centers.

Our Expertise

Our team of degreed engineers brings deep expertise in quality assurance, reverse engineering, and advanced measurement technologies. With certifications in Tolerance Stacks, GD&T, and Six Sigma methodologies, we deliver precise solutions for complex engineering challenges across aerospace, automotive, manufacturing, medical device, and other industries.

Advanced Technology and Certification

We maintain ISO/IEC 17025 certification for our measurement and calibration services, ensuring that our dimensional inspection results meet the highest industry standards for accuracy and traceability. Our metrology lab features cutting-edge equipment including:

- Industrial laser and long range laser scanning systems

- Structured light scanning technology

- High-precision touch probe and scanning coordinate measuring machines (CMMs)

- Industrial CT scanning with NAS410 Level 3 certification

- Long-range laser tracking systems

- Advanced multi-sensor vision systems

- Advanced point cloud processing software

Complete Services

From 3D scanning and reverse engineering to first article inspections and surface modeling, we provide complete metrology solutions. Our services include dimensional inspection, non-destructive testing, failure analysis, and CAD modeling using industry-leading software platforms including Siemens NX, SolidWorks, Creo, and Revit.

Federal Licensing and Security

3D Engineering Solutions holds both Federal Firearms License (Type 07 Manufacturer FFL) and Federal Explosives License (Type 20 manufacturer FEL), allowing us to serve defense and security applications. We are ITAR registered and employ only U.S. citizens for sensitive projects.

Our Commitment

We define fast turnaround with measurement capabilities reaching 1,000,000 points per second, while maintaining precision and accuracy. Whether you need emergency troubleshooting support or reverse engineering services, our team stands ready to deliver the quality and responsiveness your projects require.

Frequently Asked Questions

What is surface modeling?

Surface modeling involves creating precise digital representations of physical part surfaces using advanced CAD software. We create both Class A and Class B surfaces depending on your specific requirements, with Class A surfaces providing the highest level of continuity and smoothness.

What file formats can you deliver?

We deliver surface models in your preferred CAD format, including native files for SolidWorks, NX, Creo, and other major platforms. We can also provide neutral formats like STEP, IGES, or STL files as needed.

How long does surface modeling typically take?

Project timelines depend on part complexity and the level of detail required. Simple surfaces may be completed in a few days, while complex freeform surfaces with tight tolerances may require several weeks. We provide detailed timelines during our quoting process.