Geometric Dimensioning and Tolerancing: Professional GD&T Services

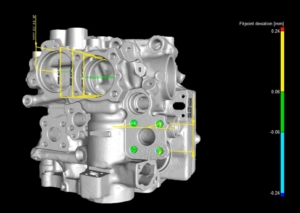

Our designs incorporate Geometric Dimensioning and Tolerancing (GD&T) best practices and include formal tolerance stacking analysis where critical to function. We apply our knowledge of GD&T and tolerance stacks to critically examine both old and new design files and prints for errors and inconsistencies.

We provide correction and tolerance adjustment suggestions that eliminate or mitigate potential issues. Where errors have crept into existing designs and have followed through to tooling, we provide statistical tolerancing to either alleviate concerns or provide documentation for tool change.

GD&T Fundamentals: Communicating Design Intent

Geometric Dimensioning and Tolerancing is a symbolic language used on engineering drawings to communicate design intent and control how parts are manufactured and inspected. GD&T specifies the allowable variation in form, orientation, and location of features, providing clearer communication between design engineers, manufacturers, and quality control professionals.

The system uses standardized symbols and feature control frames to define tolerances more precisely than traditional plus/minus dimensioning. Common GD&T elements include datum reference frames, which establish the coordinate system for measurements, and material condition modifiers like Maximum Material Condition (MMC) that affect how tolerances are applied.

At 3D Engineering Solutions, our certified engineers apply GD&T principles during inspection services, First Article Inspections, and reverse engineering projects. We interpret these symbols and callouts to ensure measurements align with the design engineer’s intent, whether we’re validating new tooling or creating documentation for legacy parts.

Understanding GD&T Elements in Practice

GD&T operates through several interconnected concepts that work together to define part requirements clearly. Understanding these elements is necessary for accurate inspection and measurement work.

- Datum Reference Frame: Establishes the coordinate system (points, axes, or planes) used as the foundation for all measurements

- Feature Control Frame: The rectangular symbol that specifies the geometric tolerance, including the tolerance value and applicable datums

- Material Condition Modifiers: Symbols like Maximum Material Condition (MMC) that define when and how tolerances apply based on the actual size of features

- Basic Dimensions: Theoretical exact values that locate features but have no tolerance themselves

- Datum Features: Physical features on the part used to establish the datum reference frame

During our inspection and reverse engineering work, we apply these GD&T principles to ensure measurements reflect the design engineer’s intent. Whether we’re performing First Article Inspections or creating CAD models from existing parts, proper interpretation of these concepts helps us deliver accurate, reliable results that support successful manufacturing processes.

The Cost of GD&T Errors in Production

Geometric Dimensioning and Tolerancing errors can cost manufacturers thousands of dollars in rework, scrapped parts, and production delays. When GD&T callouts are misinterpreted or incorrectly applied, parts that should function properly may fail to assemble, creating cascading problems throughout the production process.

Common costly GD&T problems include:

- Tooling Modifications: We’ve seen suppliers forced into endless loops of tooling changes because tolerance conflicts weren’t identified until First Article Inspection

- Assembly Failures: Parts that measure correctly individually but don’t function as intended when assembled due to misunderstood datum reference frames

- False Conflicts: Basic dimensions measured incorrectly create conflicts between features that don’t actually exist

- Production Delays: GD&T errors discovered during production halt manufacturing while engineers resolve tolerance issues

Proper GD&T implementation prevents these costly mistakes by clearly communicating design intent from the beginning. Our tolerance stacking analysis helps identify potential conflicts before tooling begins, saving both time and money by addressing issues in the design phase rather than during production.

At 3D Engineering Solutions, our 30 years of quality-assurance management experience has shown us how small GD&T errors can have major consequences. Our certified engineers apply this knowledge to every project, whether we’re reviewing prints for potential issues, performing First Article Inspections, or creating documentation for reverse-engineered parts. We understand that getting GD&T right the first time isn’t just about meeting specifications – it’s about ensuring successful, cost-effective production.

Applying GD&T Best Practices in Manufacturing

Proper application of GD&T requires understanding how tolerances interact with manufacturing processes and measurement capabilities. At 3D Engineering Solutions, we apply these guidelines during our inspection and reverse engineering services to ensure parts meet design intent.

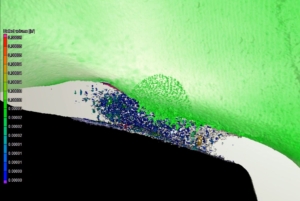

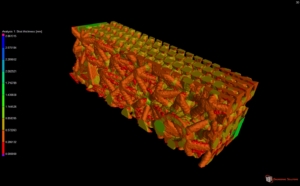

- Manufacturing Process Impact: Different processes like machining, precision casting, or molding have varying capabilities that affect how GD&T tolerances should be applied

- Measurement Uncertainty: The chosen inspection method must have adequate precision relative to the specified tolerance (we follow TUR ratios of ideally 10:1, acceptable down to 4:1)

- Material Condition Application: Understanding when Maximum Material Condition (MMC) or other modifiers apply affects the actual tolerance zone size

- Datum Hierarchy: The order of datums in the feature control frame directly impacts how the part is fixtured and measured

- Tolerance Stacking: Multiple GD&T callouts on related features must be analyzed together to prevent conflicts

Our certified engineers use these guidelines when reviewing prints for errors and inconsistencies. We can identify potential manufacturing or inspection issues early in the design phase and provide recommendations for tolerance adjustments that maintain design intent while supporting cost-effective production.

GD&T Symbol Categories and Applications

GD&T uses standardized symbols to communicate specific geometric requirements on engineering drawings. Our certified engineers interpret these symbols during inspection services to ensure measurements align with design intent.

Form

The form category controls the shape of individual features without reference to other features or datums. Straightness controls how straight a line element or axis must be within a specified tolerance zone. Flatness defines the tolerance zone within which a surface must lie, regardless of the part’s orientation. Circularity controls the roundness of circular features in cross-section, while cylindricity combines circularity and straightness to control the entire cylindrical surface.

Orientation

Orientation controls require features to maintain specific angular relationships to datum references. Perpendicularity requires a feature to be perpendicular to a specified datum within the stated tolerance. Parallelism controls how parallel a feature must be relative to a datum reference. Angularity specifies the allowable variation from a specified angle relative to a datum.

Location

Location controls define where features must be positioned relative to datums and other features. Position controls the location of features relative to datums and other features, commonly used with bolt hole patterns. Concentricity requires the axis of one feature to align with the axis of a datum feature. Symmetry controls how centered a feature is relative to a datum plane.

During First Article Inspections and reverse engineering projects, we measure these GD&T callouts using the appropriate datum reference frames. Our ISO 17025 certification ensures our measurements are traceable and reliable, whether we’re validating new tooling or documenting existing parts for reproduction.

Get Expert GD&T Analysis for Your Next Project

Whether you’re validating new tooling with First Article Inspections, troubleshooting manufacturing issues, or reverse engineering legacy parts, proper GD&T interpretation makes the difference between successful production and costly rework. Our certified engineers bring decades of tolerance stacking experience to every project, ensuring your measurements reflect true design intent.

Don’t let GD&T errors follow through to tooling or production. Our ISO 17025 certified team can review your prints for inconsistencies, provide statistical tolerancing analysis, and deliver the accurate dimensional data you need to make informed decisions. From basic form controls to complex position tolerances, we measure what matters using the right datum reference frames.

Contact us today for a quote on your dimensional inspection, reverse engineering, or GD&T analysis needs. With 24/7 availability and typically same-day quotes, we’re ready to support your most time-sensitive projects with the precision and expertise your applications demand.

Precision, Experience, and Innovation: 3D Engineering

3D Engineering Solutions brings together over 150 years of combined industry experience with cutting-edge metrology technology to deliver precision measurement and engineering services. Our team of degreed engineers operates from a state-of-the-art 24,000 square foot facility in Cincinnati, Ohio, housing a complete metrology lab and training center.

Our ISO/IEC 17025 certification ensures that every measurement we take meets the highest standards for accuracy and traceability. We maintain Federal Firearms and Explosives licenses and ITAR registration, allowing us to serve both civilian and military applications with the security and compliance our clients require.

What sets us apart is our engineering-focused approach to every project. Our staff includes NAS410 certified engineers, GD&T certified engineers, and specialists trained across all our measurement technologies. This depth of expertise means we understand not just how to collect data, but how to interpret it meaningfully for your specific application, whether that involves troubleshooting, reverse engineering, First Article Inspection, or dimensional verification.

From our centrally located Cincinnati facility, we serve clients nationwide with rapid turnaround times and the technical expertise to tackle the most challenging measurement requirements across aeronautics, automotive, manufacturing, medical, and numerous other precision industries.

Frequently Asked Questions

Why should I choose 3D Engineering Solutions?

We combine ISO/IEC 17025 certification with over 150 years of combined industry experience and state-of-the-art equipment. Our 24,000 square foot Cincinnati facility houses multiple technologies under one roof, allowing us to handle projects from $20 parts to $100,000+ scanning projects. We offer 24/7 service availability and typically turn quotes around within a day.

What services do you provide?

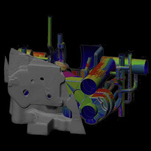

We offer 3D scanning services, industrial X-ray and CT scanning, reverse engineering, First Article Inspections (FAI), dimensional inspection, metrology services, and engineering project management. Our capabilities include laser scanning, structured light scanning, long-range laser scanning, photogrammetry, and industrial radiography with both contact and non-contact measurement methods.

What equipment do you have available?

We maintain multiple pieces of equipment for each scanning technology, including four Nikon X-ray/CT machines, industrial CT scanners, 7-axis articulating arms with laser capabilities, high-precision CMMs, large area gantry CMMs, and portable laser-based inspection equipment. Our digital x-ray systems include 160kV nano focus, 225kV microfocus, and 450kV microfocus units.