CMM Measurement & Inspection Services

Utilizing an outside service organization for dimensional inspections and validation can have significant advantages for your manufacturing and quality operations. The majority of the time spent on Coordinate Measurement Machine inspections is in the initial programming and set up of new components for measurement. Our business model is built around augmenting your CMM capabilities when you need them.

What is CMM Inspection?

CMM inspections services leverage advanced coordinate measuring machines to deliver high-precision dimensional analysis. These cutting-edge inspection tools employ sophisticated scanning technologies and coordinate measuring techniques to generate detailed point clouds of components.

Our state-of-the-art CMM equipment excels at measuring intricate geometries with unparalleled accuracy. This level of precision is vital for industries like aerospace, automotive, and medical device manufacturing, where even microscopic deviations can have far-reaching implications. Our CMM services extend beyond mere measurements, offering comprehensive quality assurance that validates parts against design specifications and proactively identifies potential issues before they escalate into costly problems.

Why You Need CMM Inspection Services

Assurance of Quality

Quality assurance forms the cornerstone of our CMM inspection services. By harnessing the power of coordinate measuring machines and advanced scanning technologies, we enable manufacturers to ensure their products consistently meet and exceed the highest industry standards.

Streamlined Production

Our CMM services significantly optimize production processes. By detecting issues early in the manufacturing cycle, we help you avoid expensive rework and minimize production delays, enhancing overall efficiency.

Enhanced Business Value

Investing in our dimensional inspection services and CMM technology can substantially boost your business value. By consistently delivering high-quality products, you’ll build a reputation for excellence that distinguishes you from competitors, fostering customer loyalty and attracting new business opportunities.

Accuracy, Speed, & Versatility

Our CMM inspection services guarantee unparalleled accuracy, ensuring components meet stringent quality standards regardless of complexity. They can swiftly adapt to diverse measurement tasks, combining speed and versatility, making them indispensable assets to your quality assurance program.

Coordinate Measuring Machines (CMM)

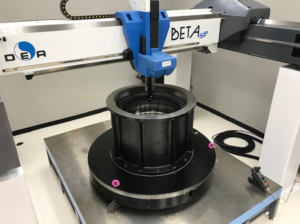

Fixed Coordinate Measuring Machines (CMM)

We utilize large volume CMMs running advanced software to capture dimensional data on parts up to 2.5 x 2.0 x 1.0 meters and 15,000 lbs. Our fixed touch probe coordinate measuring machines offer unparalleled accuracy with measurement uncertainties down to 0.0001″. These machines use probes to collect tactile data through direct contact, reducing noise and allowing for measurements in deep holes that are generally out of the ‘line of sight’ of many light-based scanning technologies. This information can either be collected by a human operator or through direct computer control (DCC). We also offer multi-sensor CMMs that combine touch probing with vision and light-based scanning.

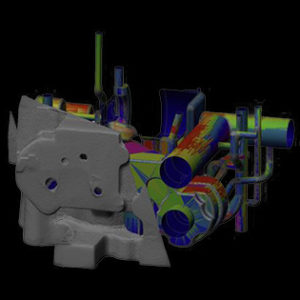

Industrial CT Scanners

Our Computed Tomography (CT) scanning technology allows internal surface metrology without disassembly. We use the latest generation of CT scanners, including metrology-grade CMMs. This adds to the standard CT equipment, which allows extreme control of part positioning, temperature and source to stage to detector calibration. As the first to add CT scanning to ISO17025 accreditation, our engineering metrologists provide unmatched insights into part interiors, including porosity, inclusions, and delamination.

Structured Light Systems

Using blue light technology, 3DES can measure objects from small medical instruments to vehicle-sized parts. This precision system uses a narrow band of blue frequencies to filter ambient light, significantly reducing data noise. A precision projector and camera capture multiple images, creating detailed point clouds through optical triangulation. Each point cloud is aligned to its neighbor by means of targets (small stickers with reflective dots) or a geometry-based alignment (when the surfaces cannot allow foreign objects [FOD] and where enough geometry is present). You are left with a point cloud representation of the entire part, enabling comprehensive dimensional analysis and future troubleshooting capabilities.

Portable Laser and Probe CMMs (PCMM)

Our 7-axis portable CMMs verify part conformance to design specifications and quality standards with unprecedented flexibility. These hybrid devices combine touchless laser scanning with precise touch probes, allowing our engineers to gather high-density geometric data efficiently. The portability and speed of our 3D laser inspection service allow on-site inspections to be performed in process, significantly reducing troubleshooting time, reducing errors, and enhancing quality assurance. With versatile mounting options including tripods, clamps, and magnetic and vacuum mounts, inspections can be completed in virtually any position.

Confocal White Light Scanning

This advanced scanning technique employs reflected light frequencies for precise measurement. The system breaks white light into different frequencies (colors), each focusing at specific distances. When an object’s surface makes contact, the frequency in focus is reflected back through that optic and will be read at a higher intensity than other reflections. Unlike traditional light-based systems, Confocal White Light scanning excels at measuring highly reflective and transparent surfaces without requiring surface treatments like paints or powders, offering superior data quality for challenging materials.

Vision Systems

Our CMM Vision Systems employ sophisticated optics to measure parts across all dimensions, capable of calculating thousands of points for each feature. While providing high accuracy in X and Y dimensions, we enhance Z-axis precision by integrating vision technology with touch probe and Confocal White Light scanning. The Zeiss true 4th Axis integration maintains precise coordinate system alignment during part rotation, ensuring comprehensive measurement accuracy.

Contact us today to see how we can augment your internal resources and capabilities.

FAQs

-

What does CMM inspection mean?

- CMM inspection is the process of using coordinate measuring equipment to quantify the geometric dimensions of an object. Using laser probes, three position sensors, linear scales, and other technological components, the coordinate measuring machine samples the measurement input and determines the relative location of a particular point.

-

What are the four main elements of CMM?

- The four main elements of CMM are the structure, probing system, controller, and metrology software. Additionally, parts like scales and air bearings may also be incorporated into CMM equipment to adjust functionality.

-

What are the types and applications of CMM?

- The main types of coordinate measuring machines are bridge CMM, cantilever CMM, gantry CMM, and horizontal arm CMM. Each have their own advantages and the best choice depends on the specific application. For example, horizontal arm CMMs are suited for measuring large surfaces while cantilever CMMs are best at measuring small parts.